In the food industry, safety is not just a standard—it is a necessity. Whether it’s an industrial catering unit, a central kitchen, or a food delivery chain, ensuring food safety compliance is essential to prevent contamination, protect public health, and maintain brand integrity. Non-compliance can lead to severe consequences including foodborne illnesses, legal penalties, and irreversible reputational damage. That’s where a comprehensive Food Safety Compliance Checklist comes into play.

This blog outlines the essential elements of a robust food safety compliance checklist and explains why each step is crucial for maintaining high food safety standards.

Why Food Safety Compliance Matters?

Food safety compliance ensures that food products are safe for consumption and are prepared, stored, and transported in accordance with regulatory guidelines. Key reasons why these matters include:

- Health Protection: Prevents contamination and foodborne diseases.

- Legal Compliance: Adherence to food safety regulations like FSSAI (India), HACCP, ISO 22000.

- Reputation Management: Builds trust among clients and consumers.

- Operational Efficiency: Streamlines food production and handling processes.

- Sustainability Goals: Supports waste reduction and responsible sourcing.

Regulatory Frameworks and Standards:

Before diving into the checklist, it’s important to understand the key regulatory bodies and standards that influence food safety compliance:

- FSSAI (Food Safety and Standards Authority of India) - Mandates hygiene ratings, licenses, and audits.

- HACCP (Hazard Analysis Critical Control Point) - International system for risk management in food production.

- ISO 22000 - Global standard for food safety management systems.

- GMP (Good Manufacturing Practices) - Focuses on hygiene and sanitation in production.

- Local Municipal Health Regulations - Guidelines at the city or state level.

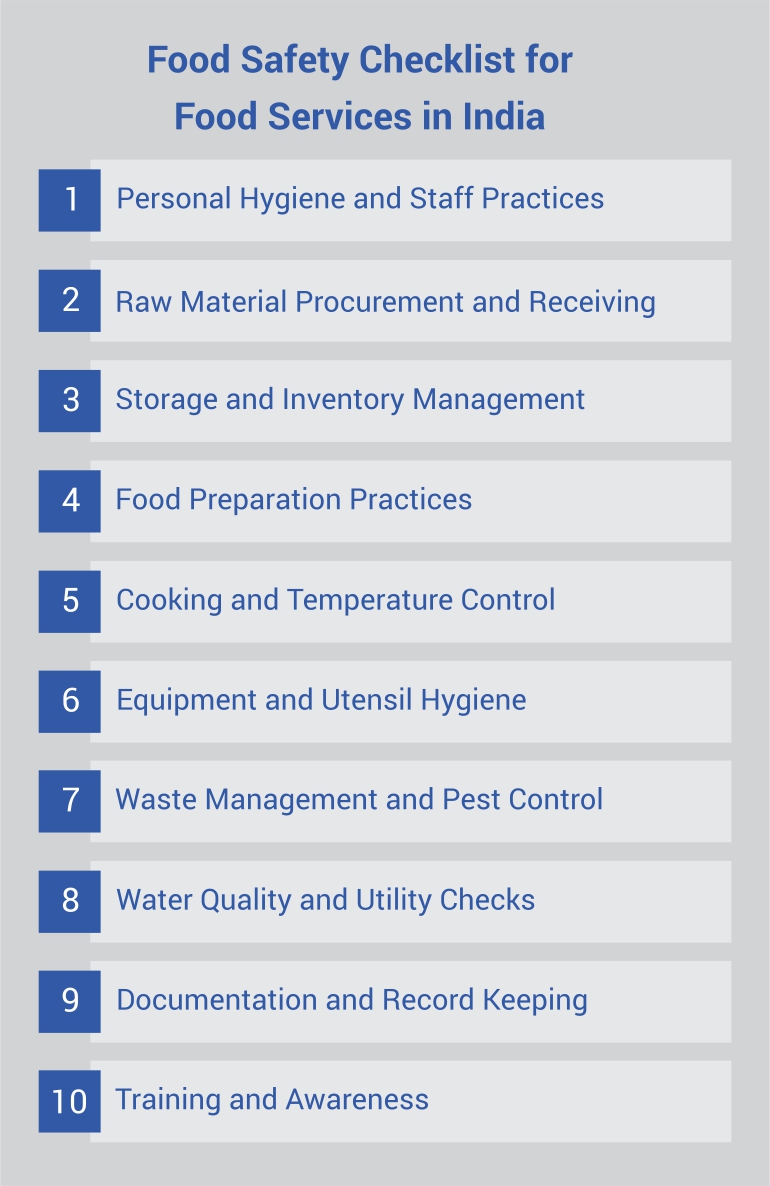

The Ultimate Food Safety Compliance Checklist

Here's a practical and structured checklist for food safety compliance covering all critical control points from sourcing to serving:

1. Personal Hygiene and Staff Practices:

Proper hygiene practices among staff members are the foundation of food safety.

- Mandatory hand washing before and after handling food

- Clean uniforms, aprons, gloves, and head coverings

- No jewelry, nail polish, or open wounds while working

- Health check-ups and vaccination records for food handlers

- Training sessions on hygiene protocols and safety standards

- Restriction of access to food prep areas for unauthorized personnel

2. Raw Material Procurement and Receiving:

Contaminated or poor-quality raw materials can compromise food safety from the start.

- Suppliers should be FSSAI/ISO certified

- Verify source, quality, and expiry of ingredients

- Maintain temperature-controlled vehicles for perishable items

- Inspect for damages, pests, or spoilage during receiving

- Document batch codes and traceability records

- Segregation of vegetarian and non-vegetarian items

2. Storage and Inventory Management:

Proper storage prevents spoilage and cross-contamination.

- FIFO (First In, First Out) inventory system

- Dry, chilled, and frozen storage areas clearly labeled

- Separate storage for raw and cooked food

- Storage areas kept clean, pest-free, and ventilated

- Regular temperature monitoring and calibration logs

- Food stored off the floor and away from walls

4. Food Preparation Practices:

The food preparation phase must follow strict hygiene protocols.

- Use of sanitized cutting boards and utensils for different foods

- Separation of allergen-prone ingredients

- Pre-cooking wash and rinse with potable water

- Controlled cooking temperatures and time logs

- Avoid handling cooked food with bare hands

- Regular cleaning and sanitizing of preparation surfaces

5. Cooking and Temperature Control:

Improper cooking is a major cause of foodborne illness.

- Use of food thermometers to ensure internal cooking temperatures

- Maintenance of hot holding (above 60°C) and cold holding (below 5°C)

- Rapid cooling and reheating procedures in place

- Avoidance of partial or undercooked food items

- Documented temperature logs for quality assurance

- All food items covered when stored post-cooking

6. Equipment and Utensil Hygiene:

Contaminated equipment can spread pathogens and allergens.

- Regular cleaning and sanitation schedules

- Use of food-grade and non-corrosive materials

- No shared utensils between raw and cooked foods

- Cleaning logs maintained with signature of responsible staff

- Dishwashing equipment serviced and sanitized routinely

- Disinfection of high-touch points like handles and knobs

7. Waste Management and Pest Control:

Food safety also involves proper disposal and hygiene outside the kitchen.

- Clearly marked bins for organic, recyclable, and hazardous waste

- Covered bins emptied regularly to avoid overflow

- Cleaning schedules for waste disposal areas

- Monthly pest control by licensed professionals

- No evidence of pest droppings, nests, or live insects

- Pest control reports and audits maintained

8. Water Quality and Utility Checks:

Water is used in almost every food process and must be safe.

- Source of water must be potable and regularly tested

- RO/UV water treatment systems maintained

- Storage tanks cleaned quarterly

- Ice used in food or drinks should be made from potable water

- Drainage systems checked for blockages or leak

- Water test certificates available for inspection

9. Documentation and Record Keeping:

Food safety is as much about processes as it is about records.

- Food Safety Management System (FSMS) documents in place

- Daily hygiene checklist logs

- Staff training and attendance records

- Allergen and nutritional labeling for packaged items

- Incident and corrective action logs

- FSSAI licenses, audit reports, and expiry date trackers

10. Training and Awareness:

Food safety is everyone’s responsibility. Ongoing training helps embed a safety culture.

- Induction training for all new food handlers

- Refresher training every 6 months

- Mock drills and emergency preparedness sessions

- Training on allergens, HACCP, and personal hygiene

- Posters and charts displayed in local language

- Feedback sessions for continual improvement

Self-Inspection and Internal Audits

Conducting regular internal audits helps in identifying gaps before external authorities do.

- Weekly hygiene inspections by kitchen supervisors

- Monthly audits aligned with FSSAI or ISO standards

- Immediate corrective action taken for non-compliance

- Review meetings with department heads

- External consultant audits on a quarterly basis

- Report filing and compliance closure timelines tracked

Technology and Digital Compliance

Digital tools can streamline food safety compliance across multiple units.

- Use of digital checklist apps for hygiene inspections

- QR code-based traceability for raw materials

- Real-time alerts for temperature fluctuations

- Automated cleaning schedule reminders

- Digital documentation for audit preparedness

- Dashboard for management to track compliance health

Emergency Preparedness

Despite best practices, food safety incidents can still occur. Be prepared.

- Emergency contact numbers displayed prominently

- Isolation procedures for suspected contaminated food

- Food recall plans in place

- First aid kits checked regularly

- Incident escalation flowchart defined

- Communication protocols with clients and authorities

Client Transparency and Feedback

Client satisfaction and feedback are essential in ensuring external checks and balances.

- Provide food composition and allergen details on request

- Encourage regular food quality feedback

- Display hygiene rating certificates and licenses at premises

- Client visits and inspections welcomed proactively

- Timely resolution of complaints with proper documentation

Conclusion: Building a Culture of Safety

Food safety is not a one-time checklist—it’s a culture that must be cultivated and sustained across all levels of operation. Whether you're managing a central kitchen, a catering service, or a corporate food delivery system, a proactive food safety compliance checklist is your strongest defense against hazards and your best asset in building customer trust.

Final Word

At FFServices, we believe that compliance is the first ingredient in any recipe for success. With a dedicated team of trained professionals, real-time monitoring, and digital compliance tools, we ensure our food catering service operations in India are always audit-ready and safety-first. Partner with us and experience food services where safety and quality go hand-in-hand.

Industries we serve:

Automobile | Ancillary | Manufacturing | Pharmaceutical | Healthcare | Oil and Gas | FMCG | Education | Real Estate | Commercial

Also read: Innovations in Industrial Catering