The Role of Robotics in the Future of Facility Management

Robotics is transforming Facility Management Solutions in India by automating cleaning, security, inspections, and maintenance. This shift helps top facility management companies boost efficiency, safety, and sustainability while optimizing costs and data-driven operations. As facilities and management evolve with AI and IoT, India’s Maintenance and Operations sector is poised for smarter, safer, and greener service delivery—reshaping the future of how facilities are managed and maintained nationwide.

Introduction

Facility Management Solutions are evolving rapidly in India, driven by the need to optimize maintenance, enhance occupant wellbeing, and reduce operating costs. Among the most transformative trends is the integration of robotics into everyday operations. From robotic cleaners to autonomous inspections, the synergy between facilities and management is becoming increasingly automated, reshaping how maintenance and operations in India are delivered. In this blog, we'll explore the rise of robotics, its benefits, real-world examples, challenges, and what lies ahead for top facility management companies in India.

Why Robotics in Facility Management?

Enhancing Efficiency and Productivity

Robots excel at performing repetitive, physically demanding tasks—without fatigue or drop in performance. This advantage is critical in facility operations like floor cleaning, surveillance, waste management, and preventive maintenance. Implementing robotic solutions in facilities and management helps reduce human error, freeing staff to focus on more strategic or sensitive tasks.

Cost Savings and ROI

While upfront investment in robotics may appear high, the long-term Facility Management Solutions clearly offset those costs. Automated systems require less overtime, lead to fewer errors, and optimize resource utilization. Moreover, predictive maintenance tools translate into fewer breakdowns and more efficient operations—key concerns in Maintenance and Operations India.

Safety and Risk Mitigation

Robots perform tasks in environments that can be hazardous—chemical storage areas, high-altitude inspections, confined spaces, or contaminated zones. This reduces workplace risk, ensuring human personnel are protected from harm.

Data-Driven Operations

Equipped with sensors and IoT connectivity, robotics generate vast amounts of operational data. Such intelligence empowers facility managers to make informed decisions—ranging from HVAC optimization to inventory planning—ushering in a new age of proactive facilities and management.

Robotics in Action: Facility Management Use Cases

Automated Cleaning Robots

Robotic vacuum and scrubber machines are now common in Indian airports, shopping centers, corporate lobbies, and hospitals. Brands like Brain Corp and Afma provide floor-cleaning robots with obstacle detection, path planning, and remote monitoring. These robots are vital for maintaining hygiene standards inexpensively and consistently.

Surveillance and Security Robots

Mobile security robots patrol properties autonomously, using cameras and advanced sensors to detect intruders or fires. Deployed in campus settings, these machines enhance the services offered by top facility management companies, enabling them to offer 24/7 security at reduced costs.

Inspection and Maintenance Robots

In industrial plants, automated drones and crawling robots inspect building façades, pipelines, electrical panels, and pump rooms. They capture real-time video, thermal images, and structural metrics—critical for Maintenance and Operations India, enabling scheduled repairs before issues escalate.

Delivery and Logistics Assistance

Some offices, hotels, and hospitals in Indian metro cities use small robots to deliver documents, room service, medicines, or packages. These bots reduce human footfall, improve service speed, and fortify hygiene protocols—an especially crucial aspect amid the COVID-19 era—and now, beyond.

Lawn and Outdoor Maintenance

Robotic mowers and weeders are making inroads into large green spaces and campuses. They automate repetitive outdoor tasks and use minimal energy, integrating smart planning with weather data and terrain understanding.

Robotics Enabling Performance Metrics

Incorporating robotics into facilities and management is more than just deploying hardware; it’s about data-driven strategies, driven by KPIs:

| Area of Operation | Robotics Contribution |

|---|---|

| Cleaning Quality | Uniform results, mapping of unclean areas, statistics |

| Task Completion Time | Automated route plans, battery management |

| Predictive Maintenance | Sensor data, condition-based alerts, problem prediction |

| Safety Compliance | Reduced human exposure, real-time hazard detection |

| Cost per Square Foot Served | Efficient use of robots, reduced manual labor costs |

Robots generate a constant data stream-machine uptime, path metrics, energy usage, thermal readings-allowing managers to benchmark and optimize.

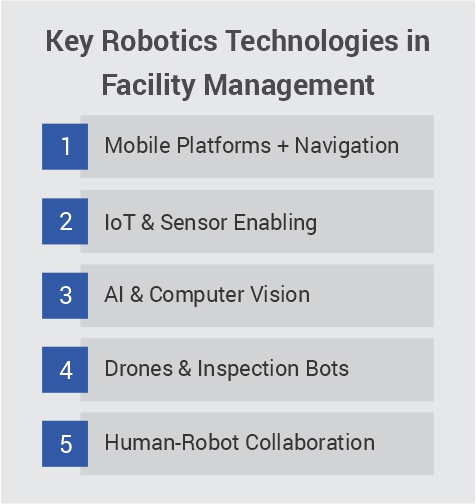

Key Robotics Technologies in Facility Management

Mobile Platforms + Navigation

Autonomous platforms with LIDAR, ultrasonic and vision-based navigation are central. They map facilities, avoid obstacles, and return to docks automatically.

IoT & Sensor Enabling

Robots integrate temperature, CO₂, motion, sound, and vibration sensors—feeding intelligent building systems and central dashboards.

AI & Computer Vision

Advanced machine learning allows for object recognition (spills, debris), anomaly detection in surveillance streams, facial recognition or PPE compliance detection, and rapid automated analysis.

Drones & Inspection Bots

In aerial and confined-space inspections, drones and rovers now capture high-res video and thermal scans, avoiding costly scaffolding or human climbs.

Human-Robot Collaboration

Robotic exoskeletons assist staff in lift/transfer tasks; collaborative cleaning robots hand over work when encountering humans; remote monitoring enables human oversight and timely manual intervention when needed.

Benefits for Maintenance and Operations India

Efficiency Gains & Speed:

Robots operate continuously or during off-peak hours—spotless walkways, routine perimeter patrols, faster turnaround for housekeeping and logistics.

Lower Downtime

Inspections based on conditions (e.g., vibration sensors on pumps) enable timely repairs, avoiding plant shutdowns and lowering facility outages.

Enhanced Safety & Compliance

Hazardous zones such as boiler rooms, chemical labs, sewer lines benefit from regular risk-free patrols. Surveillance bots raise alerts in real-time, and inspection drones monitor high-risk zones.

Quality, Monitoring & Reporting

Data-driven intervention, floor cleanliness maps, grid and sensor readings provide transparency in compliance and service-level agreements (SLAs), boosting accountability-crucial for top-tier clients.

Sustainability & Green Credentials

Robotic mowers, energy-aware HVAC bots, and optimizing device usage based on demand contribute to reduced emissions and align with ESG goals.

Challenges & Mitigation in the Indian Context

High Capital and Deployment Costs

Budget constraints can deter small-scale providers. To mitigate this, vendors offer managed-service models (Robots-as-a-Service), lease options, or outcome-based SLAs.

Workforce Displacement Concerns

There is anxiety among low-skilled employees. Many facility service leaders address this by reskilling or upskilling staff to operate and maintain robots, transforming human roles to monitoring and customer care.

Regulatory & Data Security Compliance

Videos and sensor data may involve privacy risks, especially in offices. Adhering to GDPR-style norms and ensuring data encryption, role-based access, and audit trails addresses this concern.

Performance in Diverse Indian Environments

Robots must handle dust, humidity, wet surfaces, power fluctuations, and unstructured spaces. Local vendors collaborate with global robotics OEMs to customize hardware and calibrate vision systems.

Acceptance and User Experience

Employees and visitors must trust robots. Pilot phases with clear signage, real-time dashboards, and staff engagement events help build acceptance, especially in hospitality and retail settings.

Success Stories & Case Studies

Mall Cleaning Automation

A major commercial mall in Mumbai adopted floor-scrubber robots that operate during non-peak hours. It reduced chemical and water usage by 30% and improved cleaning consistency in corridors and food courts. The brand uses robotic dashboards to monitor coverage and refill alerts—making operations more transparent and eco-friendly.

Industrial Pump-Room Inspections

A manufacturing plant in Pune deployed wheeled robots equipped with thermal and vibration sensors to inspect pumps and motors. Compared to monthly manual checks, the robots run hourly cycles, detecting anomalies before failures occur-reducing unplanned downtime by over 40%.

Airport Security Bots

An airport in Delhi implemented mobile surveillance robots to patrol during night hours. They provide independent roaming, obstacle avoidance, and real-time video and audio alert systems. With two rotating shifts of robots, security personnel monitor coverage from control rooms—reducing the need for foot patrols and boosting coverage.

The Role of Top Facility Management Companies

Leaders like JLL, CBRE, and global players in India have established labs and innovation hubs. Here’s how they shape the future:

- Technology Pilots:Extensive trials with cleaning, security, inspection, and lawn robots in corporate, healthcare, and manufacturing setups.

- Digital Twin Integration:Facilities are recreated in digital avatars to simulate robot routing, safety zones, and resource scaling before rollout.

- Robotics Ecosystem: Partnerships with OEMs, startups, ISVs, and universities to accelerate innovation and localize hardware.

- Skill Transformation:Teams of field staff are redeployed to robotics monitoring, ticket management, and service orchestration-ensuring minimum workforce displacement.

- Sustainability & KPIs: Robotics deployments report GHG reductions, resource savings, SLA attainment, and customer satisfaction-key for ESG targets.

Conclusion

The integration of robotics into facilities and management isn’t futuristic—it’s a necessary evolutionary step for delivering high-quality, sustainable, and safe Facility Management Solutions across India. As top facility management companies adopt robotics widely, those who leverage automation, data, and human-robot synergy will stand out in this competitive domain.

With clear planning, aligned with maintenance and operations in India, and iterative deployment strategies, robotics can deliver:

- Faster, safer, and more consistent cleaning and security.

- Predictive, condition-based maintenance.

- Lower costs per square foot with improved SLAs.

- Enhanced green credentials and sustainability.

- A technological moat in bid proposals and client pitch decks.

The future is not about replacing humans—it’s about equipping them with the right tools to focus on people, strategy, and innovation. The marriage of robotics with facility management marks a significant inflection point—one that can elevate India’s infrastructure and service economy to new heights.

Industries we serve:

Automobile | Ancillary | Manufacturing | Pharmaceutical | Healthcare | Oil and Gas | FMCG | Education | Real Estate | Commercial

Also read: The Growing Demand for Zero-Waste Facility Management